专业实力

大型储罐预制安装

Prefabrication and installation of large storage tanks

中石化第四建设有限公司对各类储罐具有从土建基础、板材处理、主体安装、防腐保温以及配套的泵站、工艺管线、电气仪表安装、调校及投料保运的综合施工和管理能力,并以施工专业化、预制工厂化、焊接自动化确保所承建各类储罐工程的安装达到高质量、高速度、高水平。

Sinopec Fourth Construction Co., Ltd. has comprehensive construction and management capabilities for various types of storage tanks, including civil engineering foundation, plate treatment, main installation, anti-corrosion and insulation, as well as supporting pump stations, process pipelines, electrical instrument installation, calibration, and feeding and operation guarantee. With construction specialization, pre production factory ization, and welding automation, it ensures that the installation of various types of storage tank projects undertaken reaches high quality, speed, and level.

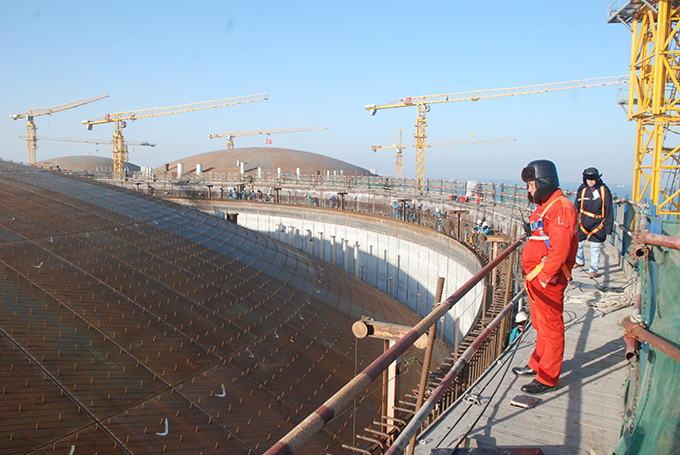

LNG储罐外罐钢筋绑扎作业

LNG储罐外罐钢筋绑扎作业 LNG储罐浇筑作业

LNG储罐浇筑作业 LNG储罐拱顶吊装

LNG储罐拱顶吊装 LNG储罐底板焊接

LNG储罐底板焊接 LNG储罐内罐气吹顶升作业

LNG储罐内罐气吹顶升作业 LNG储罐内罐壁板下料

LNG储罐内罐壁板下料 LNG储罐主体及管廊

LNG储罐主体及管廊 球罐组焊安装

球罐组焊安装大型电气,仪表及DCS,ESD安装调试

Large scale electrical and instrumentation

DCS and ESD installation and debugging

中石化第四建设有限公司在电气、仪表、DCS及ESD安装调试、计量器具检定等领域在同行业中具有独特的技术优势。公司具有大批经验丰富的专业工程师和技术精湛的师,配备有技术先进、齐全配套的电气、仪表施工机具和设备。

Sinopec Fourth Construction Co., Ltd. has unique technological advantages in the same industry in areas such as electrical, instrumentation, DCS and ESD installation and commissioning, and calibration of measuring instruments. The company has a large number of experienced professional engineers and skilled teachers, equipped with advanced and complete electrical and instrument construction machinery and equipment.

天津乙烯工程中控室中交

天津乙烯工程中控室中交大型机组安装调试

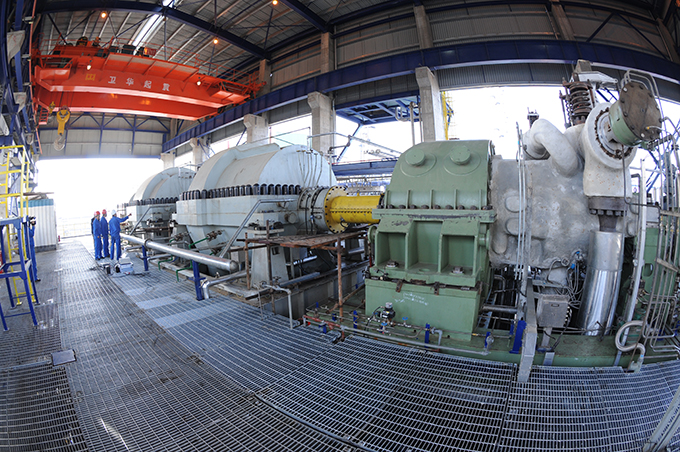

Large scale unit installation and commissioning

中石化第四建设有限公司对于大功率离心式、往复式和螺杆压缩机、各种机泵、透平、电机和烟机等机电设备的安装、调试改造,具有丰富的施工经验,具备异地同时安装40台大型机组的施工能力。近几年,先后在南京扬子—巴斯夫60万吨/年乙烯装置大型裂解气压缩机组、大庆高压聚乙烯装置大型高压往复式压缩机组、哈尔滨炼油厂250万吨/年催化裂解装置烟气轮机-轴流式主风机同轴器机组、天津100万吨/年乙烯工程乙烯装置裂解汽GB201压缩机组、内蒙古中天合创项目煤气化装置磨煤机安装等大型机组安装、调试中取得骄人业绩,均实现一次试车成功。

Sinopec Fourth Construction Co., Ltd. has rich construction experience in the installation, commissioning, and transformation of high-power centrifugal, reciprocating, and screw compressors, various pumps, turbines, motors, and flue gas turbines, as well as other mechanical and electrical equipment. It has the construction ability to simultaneously install 40 large units in different locations. In recent years, we have successively installed large-scale cracking gas compressor units in the Nanjing Yangzi BASF 600000 ton/year ethylene plant, large-scale high-pressure reciprocating compressor units in the Daqing high-pressure polyethylene plant, flue gas turbine axial flow main fan coaxial unit in the Harbin Refinery 2.5 million ton/year catalytic cracking plant, and cracking gas GB201 compressor units in the Tianjin 1 million ton/year ethylene project ethylene plant The Inner Mongolia Zhongtian Hechuang project has achieved remarkable results in the installation and commissioning of large-scale units such as coal gasification equipment and coal mills, all of which have achieved a successful trial run.

天津100万吨乙烯及配套工程乙烯装置裂解汽GB201压缩机组安装

天津100万吨乙烯及配套工程乙烯装置裂解汽GB201压缩机组安装 中天合创项目煤气化装置磨煤机安装

中天合创项目煤气化装置磨煤机安装 石家庄项目蜡油加氢循环氢压缩机组

石家庄项目蜡油加氢循环氢压缩机组 主风机粗旋安装

主风机粗旋安装电话 : 022-63862213 63862214 63862347 63862718 传真 022-25990156

技术支持:石化盈科信息技术有限责任公司